Image Credit: Pexels

The Overview

The future is electric, without a doubt! Plus, sustainability and sustainable transportation are the goal for everyone looking forward to spending their days on Earth. Moreover, as global population growth occurs rapidly (expected to reach over 10 billion by 2060) and demand for improved quality of life increases, sustainable energy consumption methods for transportation are becoming increasingly crucial.

Environment-friendly transportation and logistics solutions like electric buses (or eBuses) and trucks are becoming more critical than ever for people commuting in economy class in urban transit systems and for long-distance travel. Scientifically, commercial EV vehicles (CEVs) are best for the planet since they help us minimize global GHG emissions over time and enable cleaner air for everyone.

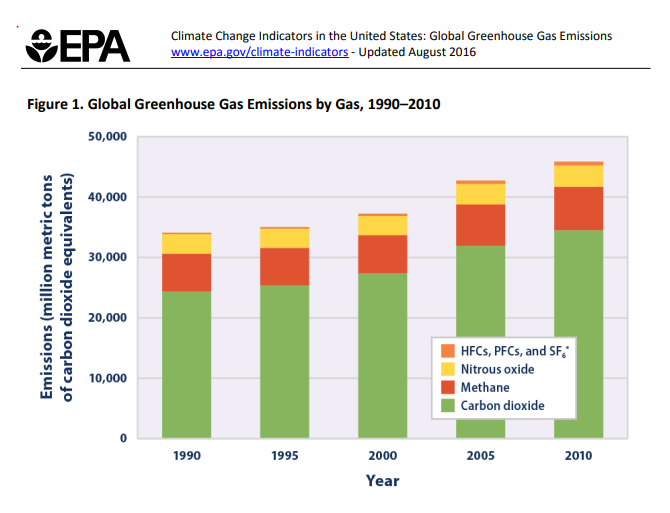

In 2010, global emissions from human activities (transportation and industries majorly) reached nearly 46 billion metric tons of greenhouse gases (GHGs), measured as carbon dioxide equivalents. This marked a 35% increase since 1990. These figures represent net emissions, accounting for land use and forestry impacts.

According to a research report in March 2023, India alone contributed around 4% to global GHGs. Therefore, commercial EVs are also well-suited for densely populated countries like India. By replacing traditional vehicles such as gasoline, CNG, or HCG-operated vehicles with EVs, BHEVs, and PHEVs, rapidly growing economies can develop healthier environments and help combat climate change on a scale.

Besides the benefits of going electric, operating electric buses in colder climates can be challenging. This is because more freezing temperatures in areas like Jammu & Kashmir, Nainital, Ladakh, or Shimla in India or Snag, Yukon, Canada, Denali, Alaska, or North Ice, Greenland can negatively affect the energy consumption for an electric bus. The colder weather can also negatively impact the charging times for EVs.

This well-researched article will explore practical strategies to optimize electric bus efficiency in harsh winter conditions. We’ll focus on tips such as preconditioning, operational practices, and teeny-tiny changes that can help electric bus operators worldwide significantly reap the fruits of their labor.

Understanding the Challenges of Colder Climates for Electric Buses

Harsh winter conditions pose several challenges for electric bus operators to operate electric buses. One of the primary reported issues is the increase in energy consumption. Energy consumption increases because of the increased demand for heating the electric vehicle’s interior (seating space) and battery. And because of this, the concept of range anxiety comes into the picture.

This additional energy demand reduces the electric bus’s overall range (how far it can travel on the road) and energy efficiency. Colder climates also negatively affect battery performance, leading to longer charging times and reduced battery capacity. Colder climates can also affect the bus’s electrical systems, potentially causing delays and other inefficiencies.

What Is Preconditioning and How Can It Help Optimize Electric Bus Efficiency?

According to psychrometry (a branch of thermal sciences), preconditioning refers to regulating air temperature and humidity before entering a system. This process can involve an air conditioning unit or a dehumidifier.

The process can also involve heating or cooling the air to achieve the environment or the conditions in which the desired system can generate the expected output. This ensures the system’s efficient performance and helps avoid issues like coil frosting or excessive condensation.

Preconditioning of an Electric Bus Typically Involves:

#1. Preconditioning Electric Bus: Battery Conditions’ Optimization for Its Optimal Performance

1. Temperature Regulation and Efficient Charging: Maintaining the battery temperature within a given range (20°C to 40°C) at its charging and discharging is crucial. Regulating the temp this way ensures that the battery charges efficiently and the maximum energy transfer is possible for performance. Incorporating this process can significantly reduce the energy consumption of an electric vehicle, like an electric bus.

2. Battery life span and efficiency: Battery preconditioning is a promising process that improves the overall efficiency of the commercial EV vehicle’s battery system. It extends the battery’s lifespan by preparing it for its best performance. It guarantees safe operation and lower energy consumption, especially on long-distance routes where consistent performance is critical.

#2. Interior Preconditioning of an Electric Bus

1. Creating a Comfortable Environment: Interior preconditioning involves heating or cooling the bus’s interior to a comfortable temperature for passengers before they board. This process is typically managed by the bus’s climate control system, which operates using the battery’s power. Hence, by optimizing this preconditioning, energy consumption can be reduced.

2. Remote and Automatic Activation: Bus operators can begin the preconditioning process remotely or automatically when parked and connected to a charging station. This preparation ensures the bus is ready for its next trip, optimizing performance and passenger comfort. This process significantly reduces the bus’s energy consumption.

3. Energy Conservation and Range Extension: Energy conservation is the best principle if electric bus operators want to minimize their buses’ energy consumption. Leveraging external power sources for preconditioning rather than relying solely on battery power helps conserve energy and extend the bus’s range.

This is beneficial in harsh winter conditions, as preconditioning maintains optimal battery temperatures, reducing the energy required for heating during operation.

Thus, by implementing preconditioning, electric bus operators can ensure that the bus is fully prepared for efficient operation, minimizing the adverse effects of colder climates on overall performance and high energy consumption issues.

Strategies Employed by Zingbus to Handle Colder Climates

Zingbus Strategies for Colder Climate Operations Involve:

Zingbus Strategy #1:

Managing Thermal Conditions at their Advanced Management: Zingbus employs experts and deploys advanced thermal management systems to maintain temperatures that favor the battery of all its buses and interiors. These systems are designed to minimize energy consumption, ensuring that the buses operate efficiently even in harsh winter conditions.

Zingbus Strategy #2:

Route Optimization: The company strategically optimizes its routes to account for potential battery range reductions due to colder weather. By analyzing historical data and weather forecasts, Zingbus can adjust its schedules, ensuring that buses have enough battery capacity to complete their routes without interruptions.

Zingbus Strategy #3:

Ontime Maintenance and Training of Its eBus Staff: Zingbus believes in implementing the concepts of the future today: a routine solid maintenance strategy and a suite of driver training programs to enhance the performance of its electric buses in harsh winter conditions. Drivers at all ebuses from zingbus are well-instructed and follow orders to ensure the utmost safety of passengers. zingbus staff is well-briefed on energy-efficient driving techniques such as gradual acceleration and effective use of regenerative braking. These modern practices improve energy recovery of the ebus during sudden stops and contribute to overall operational efficiency in challenging cold weather conditions in all of northern India region.

Teeny Tiny Changes, Better Results for the Energy Efficiency of an Electric Bus

Use of Regenerative Braking Systems: Taking advantage of regenerative braking systems in electric buses plays a vital role and enhances their energy efficiency. The generating braking system captures energy during stops, which significantly helps an ebus extend its range. It is particularly effective in stop-and-go traffic, where frequent braking occurs, allowing for energy recovery that would otherwise be lost as heat in traditional braking systems. Regenerative braking is an excellent alternative for minimizing the energy consumption of electric buses.

Optimized Charging: Scheduling charging during off-peak hours is another practical approach to reduce electric bus energy consumption. Optimizing charging methods, and times reduces operational costs. Methods designed to optimize battery charging of an ebus ensures the bus is ready for its service when needed. Additionally, leveraging fast chargers minimizes downtime, enabling buses to return to service more quickly.

Auxiliary Heating Solutions: In icy conditions, employing alternative heating methods, such as diesel or natural gas heaters, can alleviate the energy burden on the electric system and reduce energy consumption. This is especially beneficial when electric heating consumes a significant amount of energy from batteries, allowing for more efficient operation and conserving battery power. Therefore, by integrating these minor adjustments, electric bus operators can achieve better overall performance and energy efficiency.

Battery Technology and Its Role in Electric Bus Efficiency in Harsh Cold Weather

Cold weather conditions demand a robust improvement in the battery technology for an ebus. It’s essential for the effective operation of electric buses.

Here’s how cold temperatures impact battery performance and what measures can electric bus operators take to mitigate these effects:

Temperature Impact on Battery Performance and Energy Consumption

Cold temperatures significantly reduce battery capacity and efficiency, decreasing electric buses’ range and longer charging times. Engineers design batteries to help them operate optimally in the recommended specific temperature range, and when temperatures drop, their performance can be adversely affected.

For instance, studies have shown that the range of battery-electric buses can decrease by as much as 38% in cold conditions, mainly when temperatures fall between -5°C and 0°C.

Importance of Thermal Management in Energy Consumption

Effective thermal management systems are vital to counter the negative effects of cold weather on an electric bus’s energy efficiency. These systems help maintain the batteries at optimal temperatures, ensuring they function effectively and efficiently regardless of external conditions.

For example, many electric buses have advanced thermal management technologies that actively measure and adjust battery temperatures, improving performance even in harsh cold climates.

These advanced systems may include heating elements that draw a significant amount of energy from the batteries to keep them warm during operation and charging. This approach not only helps maintain battery health but also allows for faster charging times, as batteries kept between 20°C and 40°C can recharge more effectively and efficiently.

Conclusion

Bus operators operating their electric buses in cold climates experience certain challenges that necessitate a thorough understanding of how the performance of batteries and overall energy consumption can be minimized. Strategies and tips discussed in this article are well-researched, include the trusted data and are based on real-life experiences of zingbus drivers. Hence, implementing the strategies such as thermal management, battery preconditioning, leveraging regenerative braking systems, and route optimization, electric bus operators not only in India but anywhere in the colder regions in the world can significantly enhance energy efficiency and ensure reliable service during harsh colder climates in winter.

Moreover, as the push for sustainable transportation grows globally, addressing energy consumption challenges will be crucial for the broader adoption of electric buses in developing economies like India, and across the globe.

Frequently Asked Questions About Electric Buses in Harsh Cold Climates

1. How can preconditioning improve the energy efficiency and performance of electric buses in winter?

Ans: Preconditioning is a process that warms the bus’s battery and interior, utilizing grid power instead of drawing energy from the battery. This approach helps conserve battery capacity for driving, which enhances overall efficiency and extends the bus’s range in harsh cold conditions. Therefore, by ensuring that the EV’s battery is at the recommended temperature (20°C to 40°C) before starting the journey, preconditioning can significantly mitigate the effects of cold weather on performance and help address the energy consumption issue.

2. What are the key strategies Zingbus uses to handle harsh colder climates in India?

Ans: Zingbus employs several strategies to optimize electric bus performance in extreme cold weather conditions. These include advanced thermal management systems that regulate battery temperatures, optimized route planning to minimize energy consumption, and regular maintenance and driver training to ensure efficient operation. Together, these measures help maintain reliable service and energy efficiency even in challenging winter conditions across the country.

3. What are some small changes that can significantly improve electric bus energy efficiency and performance?

Ans: There are several minor adjustments that can lead to notable improvements in electric bus energy efficiency. Implementing regenerative braking helps recover energy during stops, while optimizing charging times can ensure that buses are charged when electricity rates are lower. Additionally, using auxiliary heating solutions and training drivers on energy-efficient practices can further enhance overall efficiency and reduce energy consumption by the bus.

4. How does battery capacity affect electric bus performance in harsh winter conditions?

Ans: In extremely cold weather conditions, battery capacity tends to decrease because of slow chemical reactions within the electrodes of a battery. This reduction in capacity can lead to a diminished range for electric buses. Furthermore, more energy is required to heat the bus, which can further impact performance and efficiency. As a result, understanding and managing battery capacity is crucial to maintaining optimal performance of the EV vehicle in harsh colder climates.

5. What role does thermal management play in optimizing electric bus energy efficiency and performance?

Ans: Thermal management systems are important to maintain optimal temperatures for both the battery and the interior of the bus. Thus, by avoiding energy loss and ensuring that the bus operates efficiently, these systems help maximize range and performance in colder climates. Plus, effective thermal management is essential for electric buses to perform reliably and efficiently, especially during winter season.

Leave a Reply